Independent Material Testing & Engineering Recommendation

Independent laboratory testing and engineering evaluation of gas turbine blades to assess whether rejuvenated components are technically suitable for reuse in operational service.

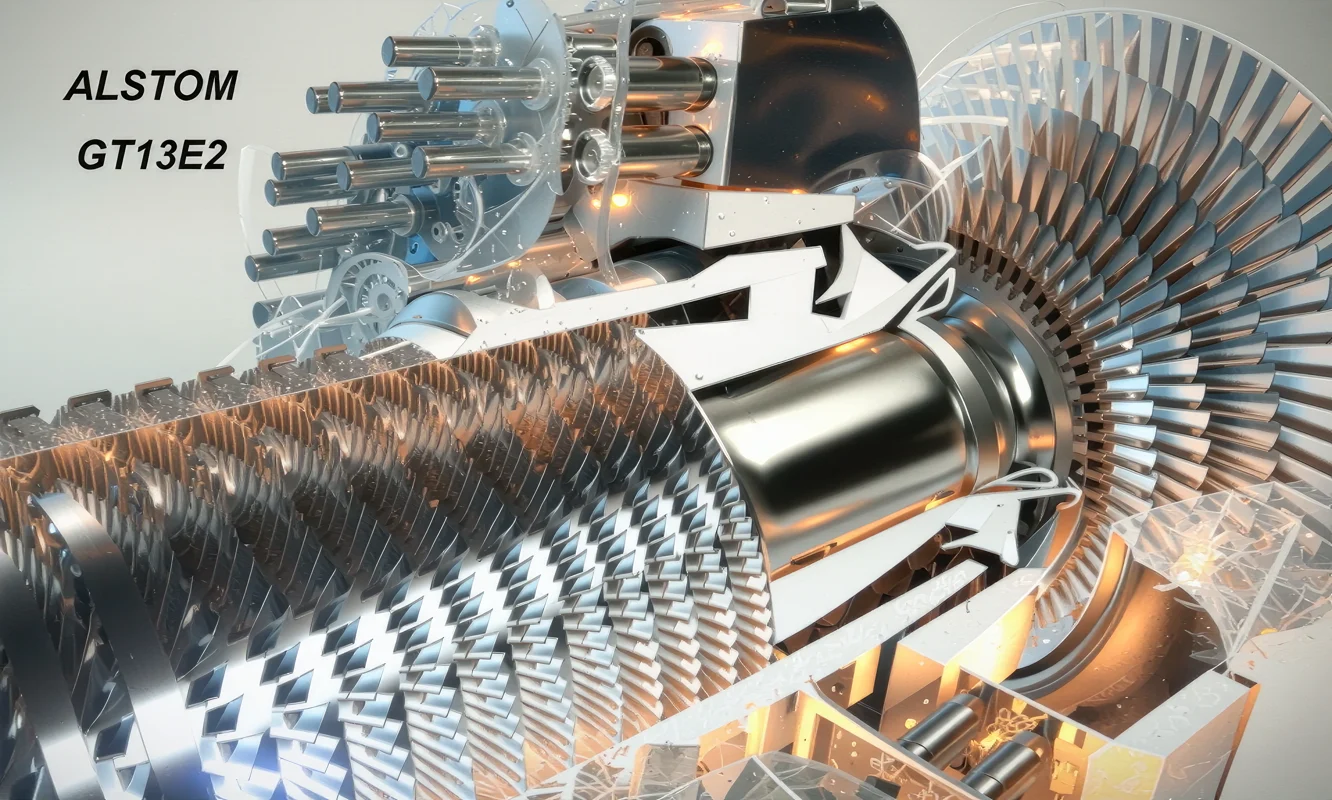

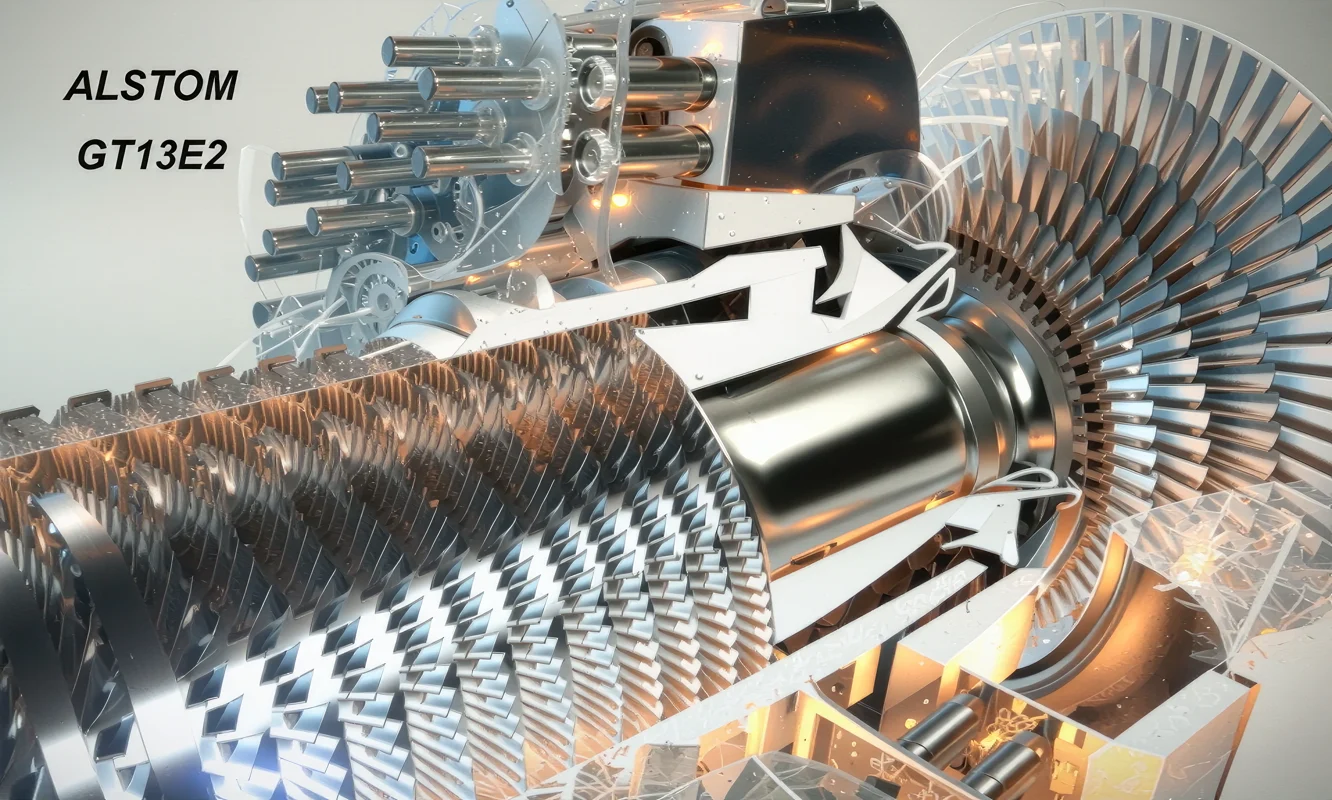

Garuda Engineering conducted an independent laboratory testing and engineering evaluation of gas turbine blades from Block 1 and Block 2 of PT. PLN Indonesia Power – UP Priok.

The objective of this project was to assess whether turbine blades that had undergone rejuvenation were technically suitable for reuse in operational service.

The evaluation involved comprehensive mechanical testing, chemical composition analysis, corrosion testing, and detailed microstructural examination. Based on the test results and metallurgical assessment, the rejuvenated turbine blades were not recommended for reuse due to material degradation and insufficient recovery of critical properties.

Gas turbine blades operate under extreme conditions, including high temperature, mechanical stress, and corrosive environments. Over long service periods, these conditions lead to microstructural degradation, loss of mechanical strength, and reduced corrosion resistance.

Rejuvenation processes are often applied to extend component life. However, post-rejuvenation verification through independent testing is essential before making reuse decisions.

This project was initiated to provide objective, data-driven engineering input for maintenance, rehabilitation, and retrofit decision-making.

Characterize the mechanical and chemical properties of turbine blades after rejuvenation

Compare test results against applicable material specifications (IN 738 LC, NIM 101)

Assess microstructural integrity and degradation mechanisms

Provide a clear engineering recommendation regarding reuse feasibility

Verify alloy composition after rejuvenation using Optical Emission Spectroscopy (OES) / XRF, compared against standard material specifications

Hardness testing using Rockwell method, tensile testing to determine yield strength, ultimate tensile strength, and elongation

Potentiodynamic polarization testing (CMS) for corrosion rate measurement in simulated environments

Optical microscopy and SEM-EDX analysis to identify dendritic degradation, carbide spheroidization, phase formation, and grain size changes

Mechanical Properties: Strength did not recover to acceptable levels after rejuvenation. Increased brittleness observed.

Metallurgical Observations: Dendritic structure deterioration, carbide spheroidization, and grain coarsening detected.

Corrosion Resistance: Reduced corrosion resistance observed due to microstructural instability.

Conclusion: The evaluated gas turbine blades are NOT recommended for reuse in operational service.

Reusing these components would pose an elevated operational and reliability risk. The rejuvenation process did not result in sufficient recovery of mechanical strength, microstructural stability, or corrosion resistance.

Laboratory test reports, SEM-EDX analysis from BRIN, mechanical and corrosion test data, metallographic images and microstructure documentation.

Garuda Engineering delivers trusted power engineering solutions through proven expertise and rigorous methodology.

"We provide objective testing, honest recommendations, and data-driven engineering support."

Before making critical overhaul or reuse decisions, contact Garuda Engineering. We provide objective testing, honest recommendations, and data-driven engineering support.