Strategic Engineering for

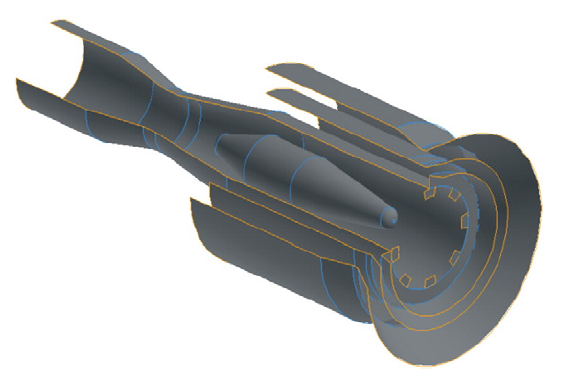

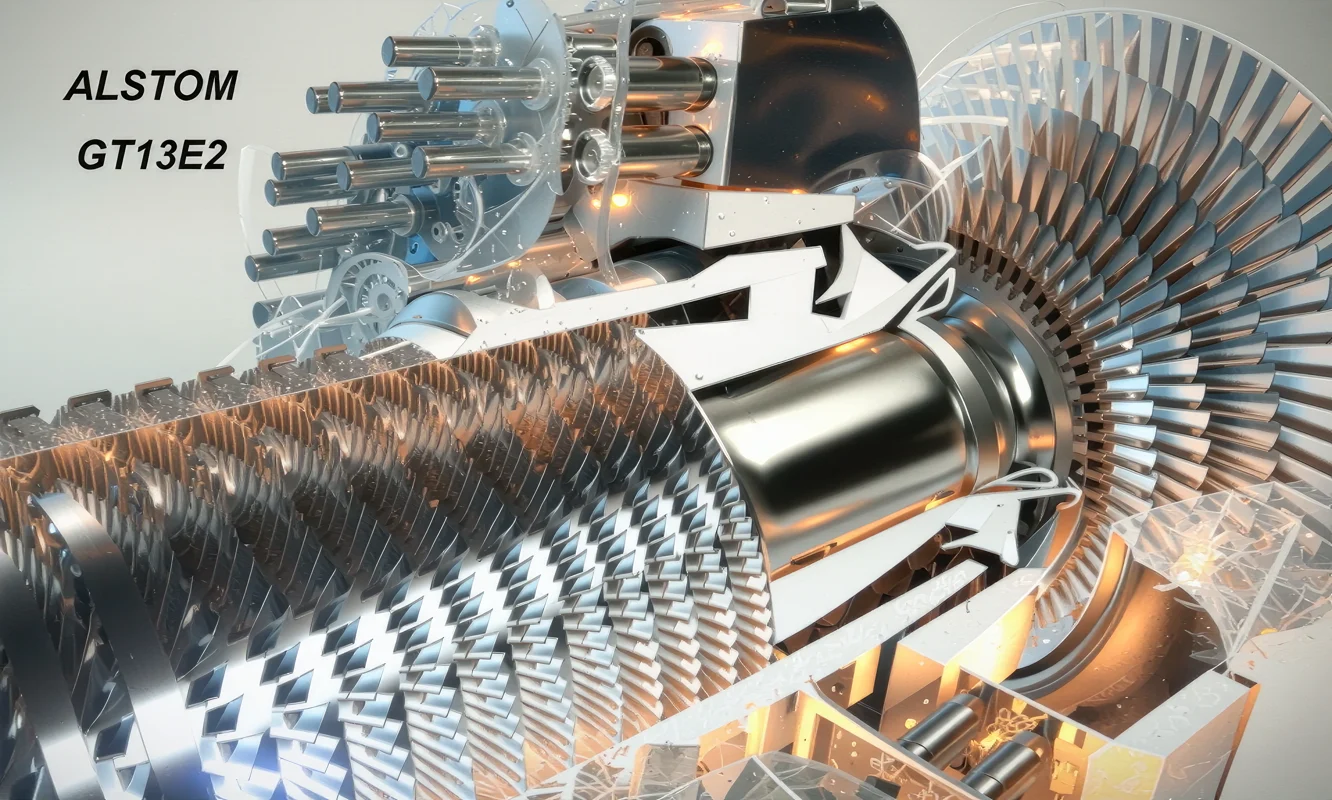

Life Extension, Uprating

& Retrofit

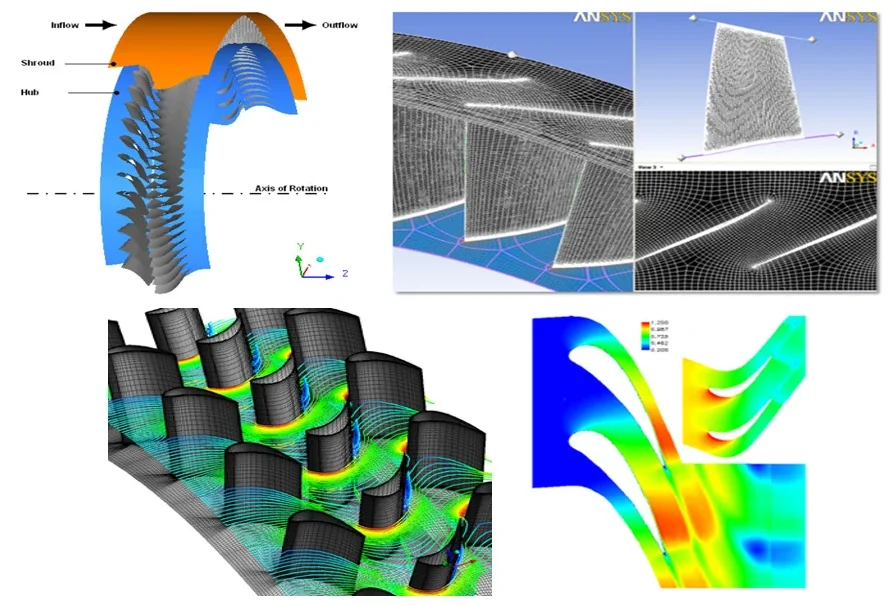

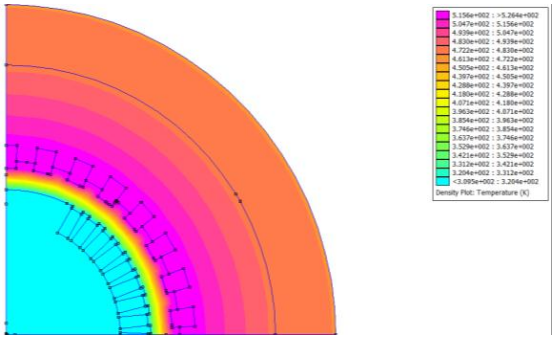

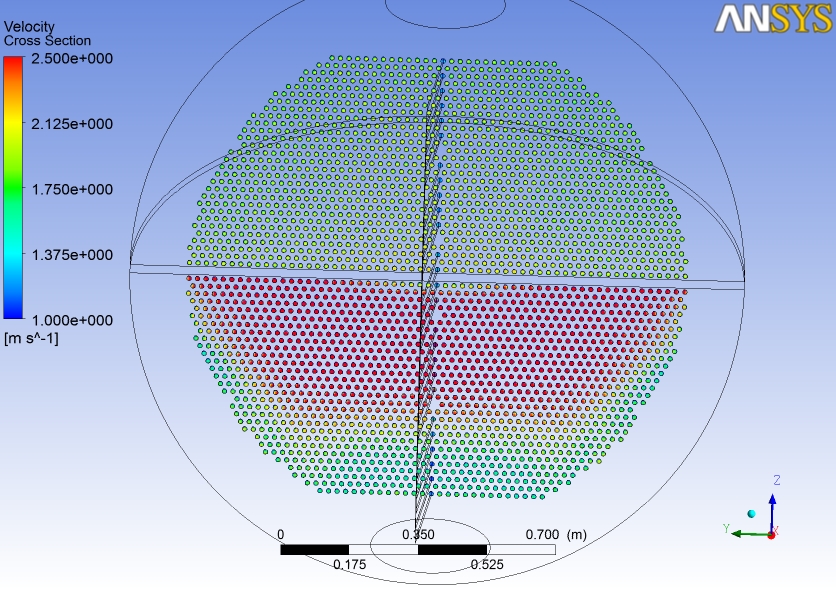

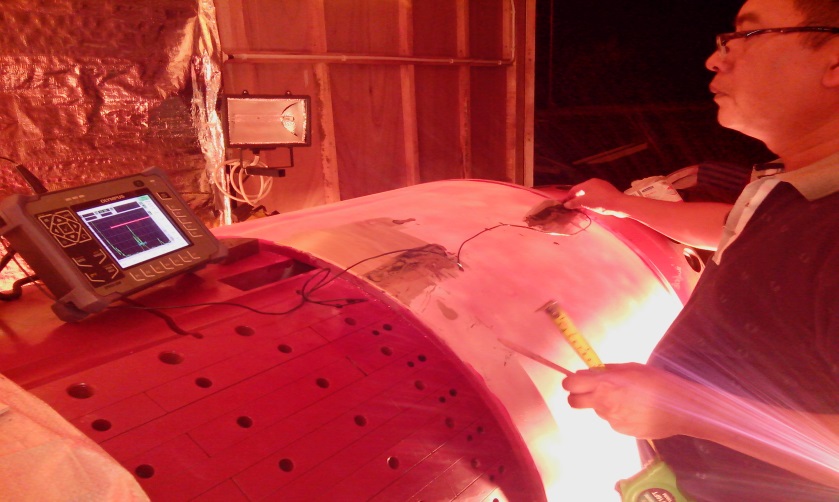

Engineering decisions driven by numerical methods (CFD/FEM) and real power plant experience across Indonesia.