400 MW Generator — Numerical Feasibility Study

Numerical-based feasibility study to evaluate design margin, thermal behavior, and magnetic performance for generator life extension and uprating.

As power plants age, operators are increasingly challenged to extend asset life while meeting higher demand without compromising reliability or safety.

This project focused on a life extension and uprating feasibility study for a 400 MW generator, using numerical magnetic and thermal analysis to evaluate whether an increase in operating capacity could be achieved within acceptable design and temperature limits.

The study was conducted entirely through engineering simulation and design review, providing a data-backed foundation for strategic operational decisions.

Increasing generator output or extending operational life introduces several technical risks:

Risk of magnetic saturation in stator core and air gap region

Excessive heat concentration in windings or core laminations

Degradation of insulation life due to elevated temperature

Reduced reliability under uprated loading conditions

The client required a clear engineering justification to determine whether uprating could be safely implemented without introducing unacceptable operational risk.

Evaluate magnetic flux distribution under uprated conditions

Identify potential saturation zones in stator teeth and air gap

Assess thermal behavior under increased electrical and mechanical losses

Determine allowable design margin for uprating and life extension

Provide an engineering-based feasibility conclusion

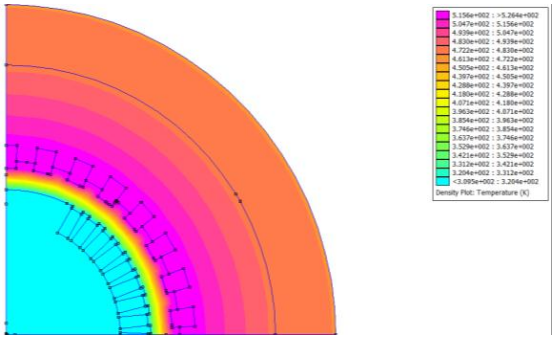

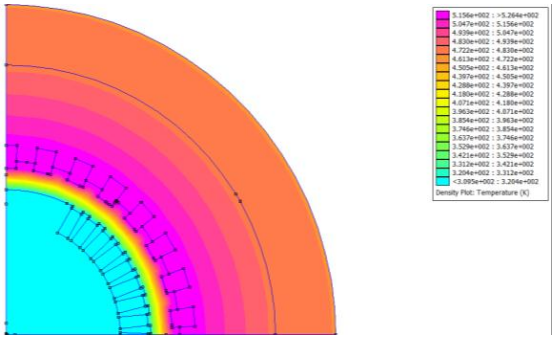

Magnetic field analysis performed numerically using FEMM 4.2:

Heat transfer analysis to assess temperature distribution:

Comprehensive evaluation of available design margins:

Engineering conclusion and recommendations:

Magnetic Analysis: Flux density levels remained within acceptable limits under uprated conditions, with no critical saturation zones identified.

Thermal Performance: Temperature distribution analysis confirmed adequate thermal margins for extended operation.

Design Margin: Sufficient design margin identified to support life extension and controlled uprating within specified limits.

Feasibility: Engineering analysis supports the feasibility of life extension and uprating with appropriate operational controls.

The numerical analysis provides a solid engineering foundation for decision-making regarding generator life extension and uprating, enabling the client to proceed with confidence based on data-driven insights.

FEM magnetic analysis results, flux density distribution, and thermal simulation outputs from the feasibility study.

Garuda Engineering delivers trusted power engineering solutions through proven expertise and rigorous methodology.

"Strategic considerations based on numerical simulation for extending service life and improving performance of power generation systems."

Looking to extend the life of your generator assets or evaluate uprating potential? Contact Garuda Engineering for a comprehensive feasibility study backed by numerical analysis.