Generator 60 MW – PLTP Dieng

In-situ inspection, structural integrity evaluation, and life assessment of generator retaining rings to ensure safe operation under high-speed and overspeed conditions.

Generator retaining rings are critical rotating components subjected to extreme centrifugal stress, shrink-fit pressure, and torsional loading. Failure of retaining rings can lead to catastrophic generator damage and significant safety risks.

This project focused on the structural integrity assessment of retaining rings for a 60 MW geothermal generator at PLTP Dieng, following concerns related to overspeed conditions exceeding 120% and recommendations from OEM inspection findings.

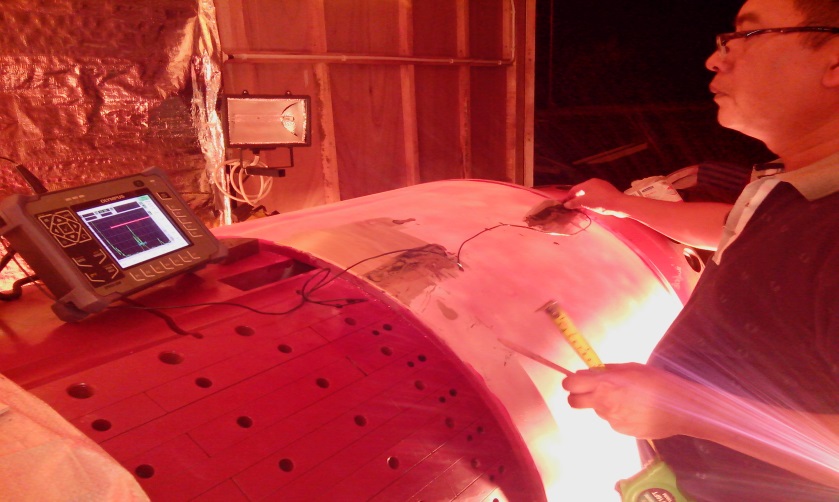

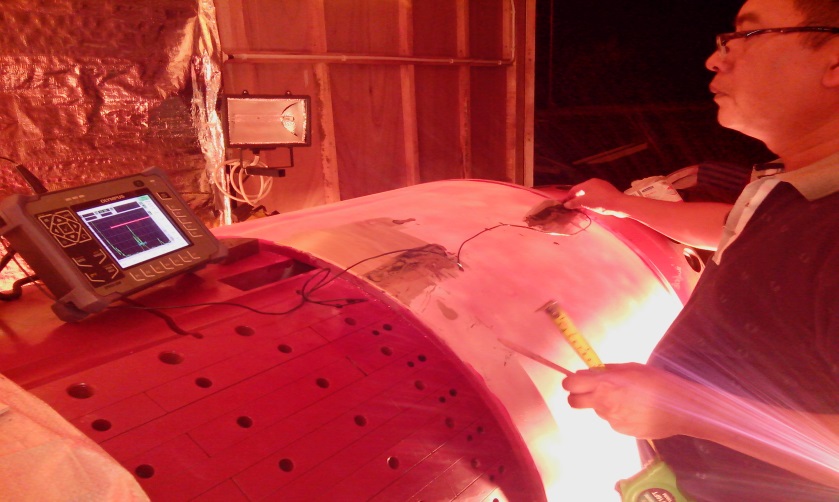

The work emphasized in-situ non-destructive testing (NDT) combined with analytical and finite element–based stress evaluation, avoiding unnecessary ring removal and minimizing outage risk.

Traditional retaining ring inspection typically requires ring removal from the rotor, which introduces significant risks and costs:

High risk of damage during removal and reinstallation

Prolonged outage duration affecting plant availability

Increased safety risks during maintenance activities

Significant maintenance and downtime costs

The generator had experienced overspeed events (>120%), raising concerns regarding shrink-fit integrity, fatigue and fretting risk, and crack initiation.

Evaluate the structural integrity of retaining rings under operating conditions

Detect surface and subsurface defects using in-situ NDT methods

Assess crack depth and flaw severity, if present

Analyze shrink-fit stress and torsional effects

Inspection for corrosion, pitting, fretting, arcing marks, and surface cracking. Identification of environmental exposure risks such as stress corrosion cracking.

Surface crack detection on outer ring surfaces. Method referenced to ASME Section V with acceptance criteria based on ASME Section VIII.

Acoustic diffraction–based crack depth gauge for determination of flaw depth beyond surface indication and verification of defect severity.

Detection of internal and subsurface flaws with axial and circumferential scanning. Referenced to ASTM A531/A531M standard.

Generator Side: No defects detected on generator side retaining ring holes.

Turbine Side: No defects detected on turbine side retaining ring holes.

Crack Assessment: Crack depth measurements showed no crack propagation.

Ultrasonic Examination: Confirmed no internal flaws or pitting detected.

Based on combined in-situ inspection results and structural stress analysis, the retaining rings were deemed safe for continued operation. No immediate corrective action or ring replacement was required. Shrink-fit and torsional stresses were within acceptable design limits.

In-situ NDT inspection records, stress analysis results, FEA models, and structural integrity assessment documentation.

Garuda Engineering delivers trusted rotating equipment integrity solutions through proven expertise and rigorous methodology.

"We ensure critical rotating components operate safely—without unnecessary intervention."

Need assurance on the integrity of critical rotating components? Contact Garuda Engineering for a structural integrity assessment.